State of the Art Additive Extrusion

Additive Manufacturing with Continuous Fiber-Reinforced Polymer Materials

(AM-CFRP)

Additive Manufacturing in general describes a process in which a part volume is created by successively adding material in a defined construction space. Today a lot of different processes with different technological maturity levels are available for a wide variety of materials like polymer, metal, ceramic or composites. The DLR Innovation Lab EmpowerAX focuses on Additive Manufacturing with fiber-reinforced polymer materials and primarily those with continuous fiber-reinforcement. For this type of material class again a lot of different additive process technology approaches are in development. Following a general overview of the state of the art in Additive Manufacturing with Continuous Fiber-Reinforced Polymer Materials (AM-CFRP) will be given. Benefits and possible obstacles for the application of these processes are discussed, existing technology providers and their processes are shown and important basic understanding of process specialties are given.

The final result of an Additive Manufacturing process with continuous fiber-reinforced materials is a polymer structure, which volume is up to a percentage of 65% filled with most likely equally distributed continuous fibers, e.g. carbon or glass. The reinforcing with continuous fibers may increase the tensile modulus by a factor of 100 and the tensile strength by a factor of 1000 compared to a pure polymer part (see State of the Art Materials). As these improved strength and stiffness is only effective in fiber direction, the orientation of the fibers should be as good as possible aligned in coincidence with the load paths of the structure. Continuous fiber-reinforced materials are a subclass of composites, which also covers short and long fiber-reinforcements. Typical applications scenarios for AM-CFRP can be divided in those aiming to add a continuous fiber-reinforced structure onto an existing part, e.g. stiffening of a shell structure, and the ones an independent part should be produced.

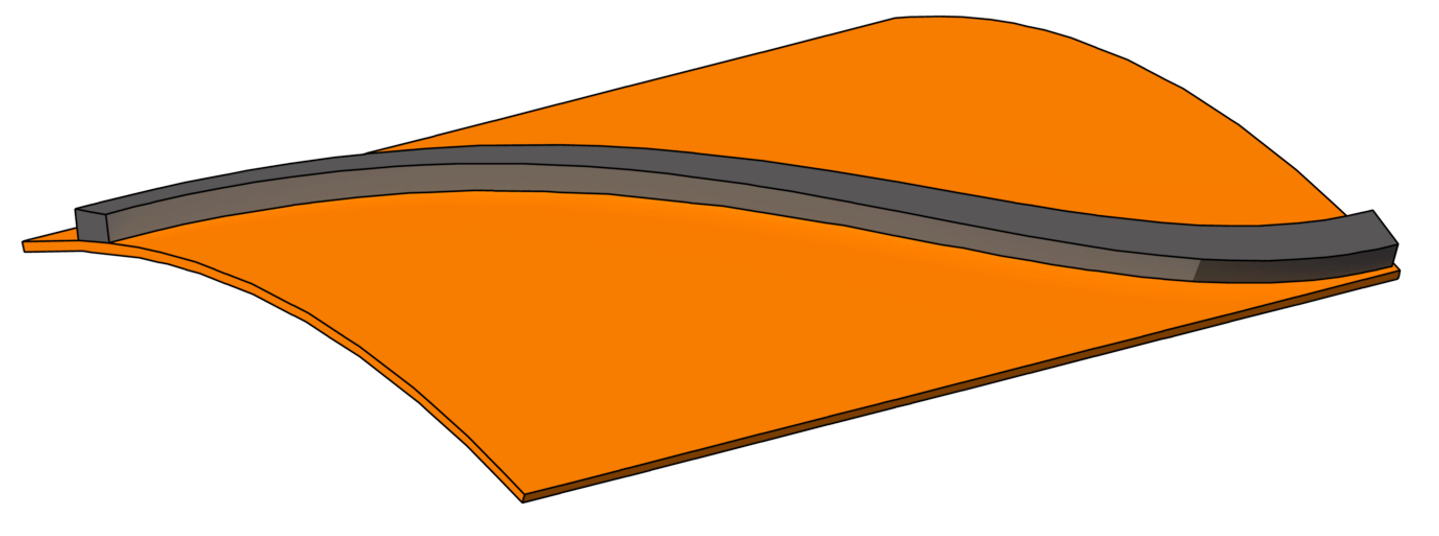

Stiffening of surfaces with continuous fiber-reinforced struts manufactured by Additive Extrusion. Source: DLR, own illustration.

All available technological approaches for AM-CFRP therefore have in common, that they somehow are able to align continuous fibers in a build volume, whereas each single fiber is enclosed by a polymeric matrix. The matrix keeps the fibers in place to ensure the geometrical dimensions and transfer the loads to the fibers. The fibers are carrying the loads and drastically increase the strength and stiffness of the part. In difference to more conventional manufacturing technologies for composite parts, AM processes promise a higher design freedom and less tooling costs utilizing highly automated equipment. An ideal AM process would be invariant against different geometries or fiber path planning and not challenge the operator with highly specific expertise. However, there is no commonly agreed strict differentiation, when a composite process is considered to be “Additive Manufacturing" or “3D-printing". As a generic process for AM-CFRP capable to deal with all kinds of materials, geometries or underlying economic conditions is not present today, each industrial available approach has its own strength and weakness. These need to be well understood to really take advantage of Additive Manufacturing with continuous fiber-reinforced materials.

Process chain of an Additive Extrusion Process.Source: DLR, own Illustration.

The first step of a typical process chain is the geometrical design (CAD) of the part to be manufactured, which also includes the fiber path planning. Afterwards this is translated into machine tool path trajectories and related machine code (CAM); simplified the build planning. Once the machine code file is finished, the Additive Manufacturing of the part can be executed. For that purpose, semi-finished fiber products like dry fiber rovings, pre-impregnated filaments or tapes are processed by an additive manufacturing end-effector / tool, the “print head". The machine code file typically contains the movement of the tool center point in the build volume as well as the tool-path related control commands for the print head. This file is interpreted by a controller, often a CNC-controller, e.g. from Bosch, Beckhoff or Siemens. For the necessary movements, the print head is assembled to a kinematic system like a 3-axis or 5-axis machine, a gantry system or a CNC-controlled robot. Some AM-CFRP processes have a multi-step approach. This means that once a preliminary continuous fiber-reinforced part or component is additively manufactured, additional process steps are necessary to get to the final part. There are different perspectives to distinguish between available AM-CFRP processes:

Polymeric matrix material

In general, there are two different classes of polymeric matrix materials used for composites. Thermoplastic materials like PA, PPS, PEI, PEKK and thermoset materials like UV-curing resins. Thermoset resins are low viscous and therefore fiber impregnation is much easier. Thermoplastics needs much higher effort for impregnation but can be molten again, as the polymeric chains do not crosslink.

Semi-finished fiber product (feedstock)

There are two main approaches. Processes working with not specially pre-treated dry fibers and those using pre-infiltrated/pre-impregnated fiber products like hybrid yarns, filaments or tapes. Especially if thermoplastic matrix materials are used, pre-impregnated products allow to reduce the process complexity as the challenging fiber-impregnation is outsourced in a preliminary and independent process step. However, the operator is tied to those materials available from certain suppliers and the initial material costs are a lot higher. By utilizing dry fibers, material costs are drastically reduced as impregnation takes place in-situ during the process. Especially for thermoplastic matrix extremely efforts need to be undertaken to ensure good impregnation quality. Therefore, systems processing pre-impregnated semi-finished products are nowadays more spread than those with in-situ impregnation, if thermoplastic matrix is required.

Consolidation

The consolidation in composites production describes the creation of the final part geometry and microstructure. Often this includes pressure and heat to compact the deposited material. Thus, voids are reduced and fiber impregnation as well as fiber distribution may be improved. Consolidation in AM-CFRP can take place as inherent property during material deposition, in-situ by directly consolidating the material in a coupled process (e.g. consolidation roller) or in an independent subsequent process step like hot pressing.

External tooling

All AM-CFRP processes need a starting point for adding new material. Most processes work with a substrate the material is deposited on like a build plate or a previously created part structure. Some processes utilize external tooling, e.g. a metal tool, which has to be specifically created for a certain geometry and fiber path planning.All available technologies for AM-CFRP combine the aforementioned points in different ways. Following it is attempted to cluster similar process schemes:

1. Direct Impregnation

Most likely dry fiber rovings are impregnated inline during the process before being deposited in build volume. The impregnation step can occur directly prior to the conveying through the print head or inside it. If the material is not getting solid again between impregnation step and material deposition in build volume, which would be a combination of in-line impregnation and direct extrusion, the continuous fiber-reinforced material needs to be pulled through the print head due to its lack of compressive rigidity.

Major advantage is that dry fiber rovings are in comparison a lot cheaper than pre-impregnated materials as feedstock and the process offers a higher material flexibility for the operator. But the incorporated impregnation process can increase the process complexity. High attention should be paid to a sufficient material consolidation.

2. Direct Extrusion

Pre-impregnated continuous fiber-reinforced fiber products, most common filaments, are conveyed through a heated nozzle to soften or even completely melt the material prior to depositing it in the build volume. As the pre-impregnated fiber products as feedstock material are solid, the conveying through the print head and deposition of material can occur due to pushing, pulling or a mixture of both.

A main benefit is the direct processing of pre-impregnated materials, which can reduce the process complexity. Also, no additional process element for polymer processing is needed. High attention should be paid to a sufficient material consolidation.

3. Co-Extrusion

Pre-impregnated continuous fiber-reinforced fiber products, most common filaments, are conveyed through a heated nozzle to soften or even completely melt the material and form a first material stream. This first stream is further mixed with a second polymer melt stream and the combined material streams are deposited in the build volume.

A main benefit is the direct processing of pre-impregnated materials, which can reduce the process complexity. Due to the addition of polymer melt to the pre-impregnated fiber product, the initial fiber volume content is reduced. High attention should be paid to a sufficient material consolidation.

4. Fiber Placement + in-situ Consolidation

These processes are really close or even identical to Automated Fiber Placement (AFP). Thermoplastic pre-impregnated continuous fiber-reinforced products like tapes with small width (slit tapes) or filaments are conveyed to the place in build volume, where they shall be deposited to a substrate. The fiber product is heated in the immediate vicinity of its placement point (nip point) to allow sufficient bonding to the substrate. Further, the deposited material is directly consolidated in a coupled process step using a compression force. Thus, material placement and in-situ consolidation constantly take place during the successive adding of material volume in build space to create a final part structure.

Due to the integrated in-situ consolidation and based on the development of Automated Fiber Placement processes in the recent years, a quite high and stable material quality may possibly be guaranteed. Based on the working principle, a suitable substrate for material deposition and carrying of consolidation forces is always required.

5. Preforming + Tool Consolidation

Most common, thermoplastic pre-impregnated continuous fiber-reinforced products like tapes or filaments are processed to preforms. These preforms can constitute simple geometrical elements like curved rods or even highly complex parts like a bracket. In a separated process step the preforms are deposited in an external tool - most likely from metal -, which represents the negative shape of the desired final part geometry. This step also allows the assembling of preforms and further adding of inserts. The final part geometry and microstructure is obtained by consolidating the preforms in the external tool, e.g. in a hot pressing or a compression molding process.

Especially if identical geometrical elements or parts have to be produced, this process approach can be beneficial. Due to consolidation in an external tool a high and stable material quality may possibly be guaranteed, but the tool needs to be designed specifically for the certain part geometry.

Benefits of AM-CFRP

The main potential benefits of Additive Manufacturing with continuous fiber-reinforced polymers are discussed below. General motivations why composite materials might be advantageous for industrial application, like the high strength and stiffness while being extremely lightweight, are not explicitly outpointed.

-

Reduced tooling costs for composite manufacturing

In conventional composite manufacturing, typically an external tool as negative form is needed to place the continuous fibers. The design and manufacturing of such tools often require high expertise, are time demanding and expensive. AM-CFRP processes ease or completely avoid necessary tooling. Some processes work with a universal build platform the material is attached to, some are first printing a tool the material is then deposited on and others at least ease the procedure of material lay-up in an external tooling.

-

Increased design freedom regarding fiber alignment

The used semi-finished fiber products in AM-CFRP have a quite low width in cross-sectional area and therefore allow highly increased geometrical resolution in the final part. In difference to wide tapes, the quite narrow deposited strands allow a lot of higher curvatures in fiber path, as the deviation of fiber path length between inner and outer boundary for small radiuses is much lower. Also, the material is added “strand-wise”, which enables a better tailoring of fiber path orientation to design needs. Especially, if compared to the use of fiber fabrics. Of course, at least the manufacturing equipment constitute a restriction, as the deposition path needs to be accessible for the print head.

-

Economic use of composites for individual parts

AM-CFRP processes show fewer manufacturing restrictions for the part design. Due to this better decoupling of design and manufacturability, the risk of detrimental effects of part design on manufacturing efficiency is reduced. The design engineers can better focus on the part requirements and considerations of “design for manufacturing” can be downstreamed. Especially for highly individual parts this reduces the efforts, typically needed in composite manufacturing for part and process design. Therefore, also single part manufacturing and small series can be economical realized from composite materials.

-

Reduced required expertise in working with composites

The handling of the anisotropic composite material is demanding in design and manufacturing, if not having been in touch with that material class before. AM-CFRP comes with highly automated process chains. Especially in manufacturing a lot of the required know-how is already included and needed operator interactions are substantially reduced. This allows production of composite parts without highly in-depth knowledge and distinct practical experience.

-

Increased resource efficiency in part manufacturing

By being an additive and not a subtractive process technology, material is only placed where it is needed. Compared to other composite manufacturing techniques, cutting waste is reduced and, due to the ability to better match material placement to structural needs, the material properties can be better exploited.Of course, for every application scenario it needs to be individually proofed, whether AM-CFRP can really create an added value. The use of pre-impregnated fiber products means increased costs for raw material and the high freedom for material placement show reduced production output ratio compared to high throughput technologies. EmpowerAX assists the assessment of technological suitability by the development of multi-stage evaluation chains and technology assessment program.

Technology Providers

A lot of different providers for AM-CFRP are on the market. Some of the available technologies belong to companies well established in composites sector, but many are related to new players in this field. Following schematic gives a short overview of available technological approaches and potential suppliers:

9T-Labs - https://www.9tlabs.com/

9T-Labs describes its technological approach as “Additive Fusion Technology” (AFT). This is a two-step process and can be related to the Preforming + Tool Consolidation scheme. The first step is a Direct Extrusion approach, in which a slit tape is reshaped inside a print head by roll forming to a strand geometry. This strand is then deposited in a build volume to print a part preform. Even complex shapes can be printed. The preform is in a second step placed in an external metal tool to consolidate the material in a hot press.

Anisoprint - https://anisoprint.com/

Anisoprint uses a Co-Extrusion approach. A pre-impregnated continuous fiber-reinforced thermoset filament is fused together with the melt flow of a neat polymer filament inside a print head. The technology is named Composite Fiber Co-extrusion (CFC).

APS Tech Solutions - https://aps-techsolutions.com/en

The technology of APS Tech Solutions can be described as a Direct Extrusion approach. A pre-impregnated continuous fiber-reinforced filament is deposited through a print head in a build volume.

AREVO - https://arevo.com/

The AQUA System from AREVO can be related to the process scheme of Material Placement + In-situ Consolidation. A pre-impregnated continuous fiber-reinforced filament is deposited in build volume and directly consolidated by a roller.

ARRIS Composites - https://arriscomposites.com/

ARRIS names its technology Additive Molding™, which can be related to the process scheme of Preforming + Tool Consolidation. Pre-impregnated continuous fiber-reinforced products are automatically shaped to preforms, which are assembled in an external tool. In the following compression molding step the material is consolidated to obtain the final part.

CEAD - https://ceadgroup.com/

CEAD uses a Co-Extrusion approach utilizing a pellet extruder for providing a main melt flow and introducing pre-impregnated continuous fiber-reinforced filaments inside the nozzle.

Continuous Composites - https://www.continuouscomposites.com/

The process of Continuous Composites is named CF3D and uses dry fiber roving which is in-situ impregnated with a thermoset resin. This infiltrated continuous fiber-reinforced material is then deposited in build volume and directly cured.

Desktop Metal - https://www.desktopmetal.com/products/fiber

The system Fiber™ from Desktop Metal can be described as micro AFP process and therefore related to the process scheme of Material Placement + In-situ Consolidation. A pre-impregnated continuous fiber-reinforced slit tape is deposited in build volume and directly consolidated by a roller.

Electroimpact - https://www.electroimpact.com/3d/overview.aspx

The Scalable Composite Robotic Additive Manufacturing system (SCRAM) from Electroimpact can be described as Material Placement + In-situ Consolidation approach. Pre-impregnated continuous fiber-reinforced slit tape is deposited in build volume and directly consolidated.

Ingersoll Machine Tools - Link follows

Ingersoll Machine Tools names its technology MasterPrint CF, which can be described as direct extrusion approach. A pre-impregnated continuous fiber-reinforced filament is deposited through a print head in a build volume.

MANTIS Composites - http://www.mantiscomposites.com/

The technology of MANTIS composites can be related to the Direct Extrusion process scheme. A pre-impregnated continuous fiber-reinforced filament is deposited through a print head in a build volume.

Markforged - https://markforged.com/

Markforged offers printers working according to the process scheme of Direct Extrusion. Pre-impregnated continuous fiber-reinforced filaments are deposited through a print head in a build volume.

Moi Composites - https://www.moi.am/

Moi composites names its technology Continuous Fiber Manufacturing (CFM), which can be described as Direct Impregnation approach. Dry fibers are impregnated inline prior to being deposited in build volume. The deposited material is directly cured in place.

Orbital Composites - https://www.orbitalcomposites.com/

The Orb 1 machine from Orbital Composites utilizes a print head capable to directly introduce dry fiber roving into a melt flow. Therefore, the technology can be described as Direct Impregnation approach.

Technological Maturity and Points of specific Attention

Available AM-CFRP processes in market show different technological maturity. In general, the development of such processes is still at the beginning and a lot of adaptions and improvements might be realized in future. Following some basic thoughts about technology readiness and points to be considered are shared.

• Availability of pre-impregnated fiber products

The availability and variety of pre-impregnated continuous fiber-reinforced semi-finished products, especially filaments, and their prices yet constitute a barrier to a wider industrial application. Also, the quality differs. Established material suppliers just started to enter the market.

• Unrestricted real 3D-capability

If a complex geometry with three-dimensional intersecting load paths has to be created, the available technological approaches reach their limits. The stiffening of highly curved, three-dimensional shells might be possible, but free hanging curved connections between separated points in free 3D-space without restrictions cannot be realized yet. Often at least kind of a substrate, like a build plate or a previously printed structure, is needed to support the material deposition.

• Design and Fiber Path Planning

If not used to composites, the design with anisotropic materials can be challenging. A new understanding for the structural layout has to be established. Industrial software solutions supporting in unrestricted three-dimensional part optimization with anisotropic materials are in development but not yet available. Especially when it comes to the fiber path planning, which needs to be done for every single strand to be deposited, there is a lack of software products for closed digital process chains. The part design (CAD) and manufacturing planning (CAM) may be one of the current biggest challenges for wide spread applicability of AM-CFRP.

• Composite Material Microstructure and Consolidation

Processes with included consolidation step currently show high microstructural material quality particularly regarding contained void content. In other process schemes special attention should be paid to this topictopic.

• Post Processing and Assembly

To obtain high quality outer surfaces or meet tight geometrical tolerances, the manufactured parts may need to be post-processed. Also, further bonding, fastening and general assembly of composite parts need specific measures.

• Design Restrictions

Typical design restrictions for AM-CFRP parts are a minimum radius of curvature to prevent fiber misalignment, a minimum fiber path length and the handling of crossing points for fiber paths. Additionally, it needs to be understood, the cross-sectional area of the deposited strands defines the possible geometrical resolution of the part structure.

• Process Integration

AM-CFRP processes show great potential to be combined with other manufacturing processes like winding, tape laying or even metal processing. This allows to better exploit the advantages of Additive Manufacturing and allows the use of well-established manufacturing methods, where additive processes not showing strong benefits. EmpowerAX provides information how process integration can be achieved and where special attention needs to be paid for.

• Quality Assurance

Considering the final part structure can consist of thousands deposited strands successively added over a large time span, the in-line quality assurance is of high importance. The process needs to be stable and reliable as one strong imperfection in a primary load path might lead to a sudden component failure, if not recognized in advance.

• Standardization and Qualification

The final part material properties are highly affected by the specific process characteristics. For AM-CFRP processes there is a lack of agreed standards and qualification procedures for spread industrial application. These are addressed in current efforts, e.g. by EmpowerAX.